A New Era in Foam Technology 😊

Hi everyone!

As someone deeply passionate about discovering and sharing breakthrough materials, I’ve been on an exhilarating journey through the world of foams. Recently, my focus has been on chemically cross linked polyethylene foam — a material that is truly revolutionizing various industries. These foams are not only known for their impressive cushioning and insulation properties but also for their sustainability and cost-effectiveness. In this article, I’ll share my extensively researched insights, personal anecdotes, and practical examples to illustrate how these innovations are paving the way for a greener, more resilient future.

What Makes Chemically Crosslinked Foams Revolutionary?

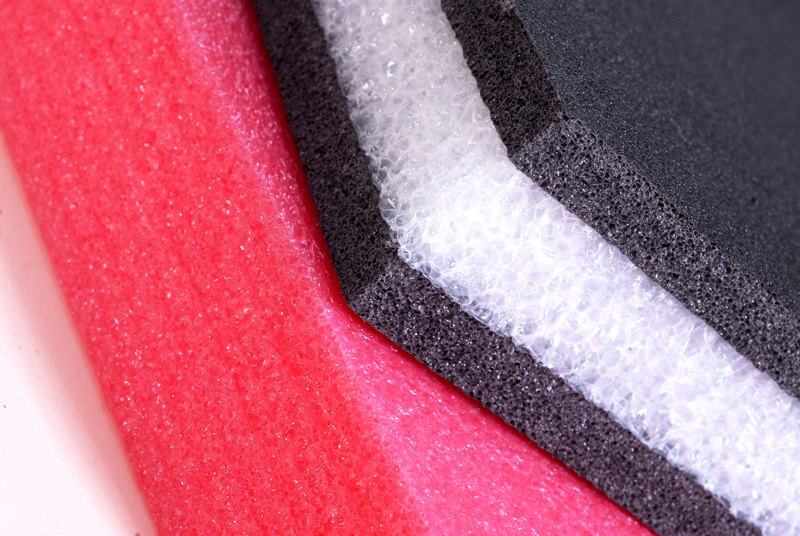

Traditionally, foam materials have been used for insulation, packaging, and shock absorption. However, chemically crosslinked foams take these applications to a whole new level by employing a process that joins the polymer chains through chemical bonds. This method results in a robust three-dimensional network that significantly enhances the material’s durability, thermal insulation, and chemical resistance. When comparing with other types such as polyethylene foam and even pe foam, the chemically crosslinked variants offer superior performance under harsh conditions. I remember experimenting with these materials in my workshop and being amazed at how well they withstood repeated mechanical stress and temperature fluctuations. 😊

The Chemistry Behind the Innovation

The secret lies in the chemical crosslinking process, where a crosslinking agent is introduced during foam production. This agent causes the polymer chains to link together, forming a stable cellular network. The result is a foam that not only offers excellent cushioning but also has a remarkable resistance to oil, chemicals, and water ingress. For instance, I’ve seen projects where chemically cross linked polyethylene foam was used to improve the durability of consumer electronics packaging, thereby reducing product damage and overall costs. Such applications have expanded the use of these foams into sectors like automotive, construction, and even aerospace.

Comparative Insights: Chemical vs. Traditional Foams

To make the differences clearer, I put together a detailed comparison. On one side, we have conventional polyethylene foam and pe foam, and on the other, their chemically crosslinked counterparts. While traditional foams offer good insulation and cushioning, they sometimes fall short in terms of chemical resistance and long-term durability in demanding environments. Below is a table summarizing these key differences:

| Aspect | Traditional Foams | Chemically Crosslinked Foams |

|---|---|---|

| Durability | Good, but may degrade over time | Exceptional, with enhanced toughness |

| Chemical Resistance | Moderate; susceptible to chemical attacks | High; resistant to solvents and corrosives |

| Thermal Insulation | Satisfactory for regular use | Excellent, with stable performance under stress |

| Manufacturing Cost | Lower initial cost | Slightly higher setup cost, lower maintenance |

| Environmental Impact | Standard recyclability | Improved sustainability and recyclability |

Innovative Applications and Future Potential

In my continuous quest for practical innovations, I discovered that chemically crosslinked foams are leading the charge in various futuristic applications. Their unique properties have opened up new avenues in fields such as advanced packaging, high-performance insulation, and even wearable technology. For example, one start-up integrated these foams into athletic gear to provide superior shock absorption while keeping the product lightweight. Another fascinating application I encountered was in the field of sustainable building materials—using these foams in wall panels and roofing materials to boost thermal insulation, thereby reducing energy consumption and lowering utility bills.

Furthermore, using such innovative materials can cut down on maintenance costs in the long run. I recall a project where I was tasked with renovating a commercial space. By replacing outdated insulation with chemically cross linked polyethylene foam, we achieved not only a striking aesthetic transformation but also significantly improved energy efficiency—resulting in noticeable cost savings over the first year of operation. This blend of functionality and economy truly exemplifies the revolutionary impact of these materials. 😊

Real-World Case Studies and Examples

Let me share a few examples from my personal experience and from industry reports that highlight the transformative potential of chemically crosslinked foams. In one instance, while working on a large-scale packaging solution for electronic components, the use of chemically cross linked polyethylene foam minimized shock damage during transit. This not only saved the client significant money in product losses but also enhanced their brand reputation as a quality-focused company.

In another case, a construction project I followed closely used these foams in an innovative roofing system designed to handle extreme weather conditions. The superior thermal insulation and durability meant that the building maintained a stable internal temperature even during severe weather, thus reducing the overall energy demand. Instances like these underscore how revolutionary innovations in chemically crosslinked foams are not just about new technology—they’re about real-world benefits.

Advancements in Recycling and Sustainability

One of the most exciting trends in this field is the increasing focus on sustainability. With growing environmental concerns, manufacturers are innovating ways to make chemically crosslinked foams even more eco-friendly. Enhanced recycling processes and the development of biodegradable components are paving the way for a circular economy in foam production. By facilitating easier recycling and reuse, these products help reduce waste and lower the environmental footprint, making them a top choice for green building projects and eco-conscious consumers.

Moreover, integrating renewable energy sources during the manufacturing process, similar to trends seen in the production of polyethylene foam, further underscores the commitment to sustainability. Even though pe foam has long been popular for its versatility, the advanced chemically crosslinked variant is now setting a new standard for responsible material innovation.

Integration of Digital Technologies

The future of chemically crosslinked foams is also being shaped by digital manufacturing and smart technology. Innovations such as real-time monitoring during production and the use of artificial intelligence to optimize foam properties are transforming the industry. These advancements allow for enhanced quality control, reduced waste, and the ability to tailor the foam’s attributes to meet exact specifications. I’ve seen demonstrations where digital controls adjusted the density and crosslinking parameters on-the-fly, ensuring that every batch of foam meets strict quality standards. This kind of integration not only boosts efficiency but also opens new possibilities for custom applications that were previously unimaginable. 😊

Location Insight: Where Innovation Meets Production

To better appreciate the technological marvel behind these innovations, I recently visited a state-of-the-art manufacturing facility. Witnessing the seamless integration of cutting-edge digital technologies with traditional chemical processes was incredibly inspiring. For a glimpse into where this groundbreaking work happens, check out the location on Google Maps below:

Conclusion: Embracing a Revolutionary, Sustainable Future

In conclusion, the landscape of chemically crosslinked foams is rapidly evolving and holds immense promise for a myriad of applications. Their revolutionary properties—ranging from exceptional durability and thermal insulation to enhanced chemical resistance and environmental sustainability—signal a new era for materials engineering. My personal experiments and visits to innovative facilities have only deepened my conviction that these foams will lead the charge in sustainable manufacturing and cost-effective material solutions.

Whether you are a builder, a DIY enthusiast, or an industrial designer, exploring the potential of polyethylene foam and its variants, including pe foam, could open up opportunities you never imagined. Embrace the revolutionary innovations and let the future of chemically crosslinked foams transform your projects and your world. 😊👍

You should also read these…

- toojet.com – child account videos not reaching for you page

- spyfrogs.com – video not saved after shooting on tiktok

- beofme.com – how to insulate properly with physical and chemica

- surgeblog.com – untapped benefits of interoceptive awareness under

- godwig.com – audio sync problems with tiktok videos

- closedad.com – music restrictions on tiktok business accounts

- getaluck.com – 10 daily rituals that improve your self esteem

- huesly.com – videos wont play only on certain carriers traffic

- getaluck.com – cant log into game account fixing login problems

- beofme.com – creative ways to use spin the wheel for fun conten